Purpose: The primary purpose of a chain belt drive guard is to prevent accidental contact with the moving parts of the drive system, including the chain, sprockets, belts, and pulleys. These components can pose a significant hazard to personnel if not properly guarded, as they are capable of causing entanglement, pinching, or crushing injuries.

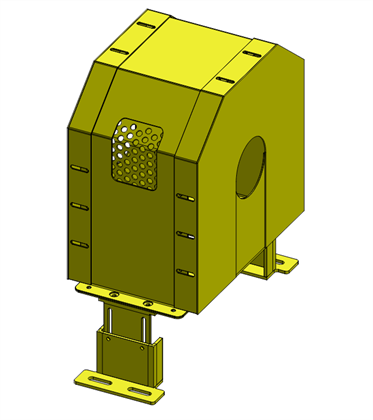

Construction: Chain belt drive guards are typically constructed of durable materials such as metal or heavy-duty plastic. They are designed to fully enclose the drive system, providing a physical barrier between the moving parts and personnel working in the vicinity. The guards may feature openings or ventilation slots to allow for cooling airflow while still preventing access to the rotating components.

Design Features: Chain belt drive guards come in various designs and configurations to accommodate different types of drive systems and applications. They may be hinged or removable to facilitate installation, maintenance, and inspection of the drive components. Some guards may also include transparent viewing windows or inspection ports to allow operators to visually check the drive system without removing the guard.

Mounting: Drive guards are securely mounted to the equipment or machinery housing, ensuring they remain in place during operation. Proper mounting is essential to prevent the guard from becoming dislodged or damaged, which could compromise its effectiveness in protecting personnel.

Compliance: Chain belt drive guards should comply with relevant safety standards and regulations, such as those established by organizations like OSHA (Occupational Safety and Health Administration) or ANSI (American National Standards Institute). Compliance ensures that the guards provide adequate protection for personnel and meet industry safety requirements.

Maintenance: Regular inspection and maintenance of chain belt drive guards are necessary to ensure they remain in good working condition. This includes checking for signs of damage, corrosion, or wear and addressing any issues promptly to maintain the guard's effectiveness in preventing accidents and injuries.

Leave a Reply

Related Products

You Might Like Also

pump coupling safety guard

The pump coupling Guard prevents access to exposed pinch-points around couplings and rotating shaft applications. This guard is designed for the 360 degrees guarding concept. These guards are ANSI/OSHA compliant. Read More

bench grinder machine safety guard

bench grinder machines are critical to protect operators from potential hazards such as flying debris, sparks, and accidental contact with the grinding wheel. Read More

Lathe machine safety guard

r lathe machines are essential to protect operators from potential hazards such as flying debris, rotating parts, and accidental contact with moving components. Read More

safety guards

Increase operator safety by machine perimeter guarding with the highest quality and visual appalling safety fence Read More

drilling machine safety guard

Drilling machine safety guards are crucial for protecting operators from potential hazards when using a drilling machine. These guards help prevent accidents and injuries that can occur due to contact with rotating drill bits, flying debris, or other moving parts of the machine. Read More

safety fence industrial

Perimeter machine guards refer to a barrier placed around a work area where an automated piece of equipment-like a robotic arm-performs a function. IES offers a wide range of perimeter guarding solutions for customers, We have modular safety panels made of Mild steel, SS 304, SS 316, We also provide a perimeter guarding solution in polycarbonate panel (PC) for high durability and visibility. Read More

Comments

Being a reliable supplier, We has the widest range of machining inserts available at affordable prices. We only offer first-class machining inserts to all our customers. Plus, our machining insert is capable of doing numbers of machining equipment and grind productivity to a halt.

For 10 years in this industry, We Cutting Tools Co. Ltd had established a perfect internal management system that controls and manages the standard quality of each product. Our company has achieved a good reputation in both domestic and overseas market by producing premium products.