Safety guards are crucial components of drilling machines to prevent accidents and protect operators from hazards. Here are some key points about drilling machine safety guards:

Purpose: Safety guards are installed on drilling machines to shield operators from rotating parts, flying debris, and other potential hazards associated with drilling operations.

Types: There are different types of safety guards designed for drilling machines, including:

- Point-of-operation guards: Cover the drill bit area to prevent contact with moving parts during operation.

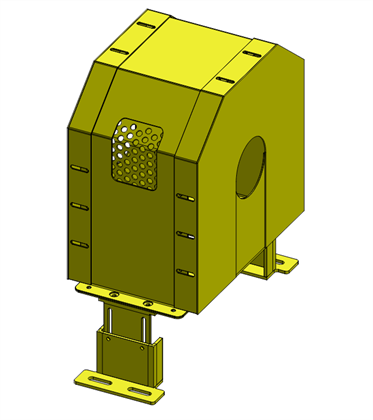

- Belt and pulley guards: Protect operators from entanglement in rotating belts and pulleys.

- Chip guards: Shield operators from flying debris and chips generated during drilling.

- Power transmission guards: Cover gears, chains, and other transmission components to prevent accidental contact.

Design: Safety guards should be robust, securely fastened, and designed to withstand the forces and pressures encountered during drilling operations. They should also be easy to adjust and maintain.

Interlocking Mechanisms: Some drilling machines are equipped with interlocking mechanisms that prevent the machine from operating unless the safety guard is properly in place.

Inspection and Maintenance: Regular inspection and maintenance of safety guards are essential to ensure they remain effective. Any damaged or missing guards should be promptly repaired or replaced.

Operator Training: Operators should be trained in the safe use of drilling machines, including the importance of safety guards and proper procedures for their use.

Regulatory Compliance: Compliance with relevant safety standards and regulations, such as those set by OSHA (Occupational Safety and Health Administration) in the United States or similar authorities in other countries, is essential to ensure a safe working environment.

Risk Assessment: Employers should conduct risk assessments to identify potential hazards associated with drilling operations and implement appropriate control measures, including the use of safety guards.

Leave a Reply

Related Products

You Might Like Also

chain belt drive guard

V Belt/Chain Drive guards fully enclosed V-Belt Safety Guards, gear drive, and belt drive power transmission system to prevent access to the pinch points around the conveyor belts, fan drives, blower drives, compressor, grinder, and crusher equipment. It helps to keep safe worker/operators around the drive from entanglements Read More

pump coupling safety guard

The pump coupling Guard prevents access to exposed pinch-points around couplings and rotating shaft applications. This guard is designed for the 360 degrees guarding concept. These guards are ANSI/OSHA compliant. Read More

bench grinder machine safety guard

bench grinder machines are critical to protect operators from potential hazards such as flying debris, sparks, and accidental contact with the grinding wheel. Read More

Lathe machine safety guard

r lathe machines are essential to protect operators from potential hazards such as flying debris, rotating parts, and accidental contact with moving components. Read More

safety guards

Increase operator safety by machine perimeter guarding with the highest quality and visual appalling safety fence Read More

safety fence industrial

Perimeter machine guards refer to a barrier placed around a work area where an automated piece of equipment-like a robotic arm-performs a function. IES offers a wide range of perimeter guarding solutions for customers, We have modular safety panels made of Mild steel, SS 304, SS 316, We also provide a perimeter guarding solution in polycarbonate panel (PC) for high durability and visibility. Read More

Comments

Our carbide inserts allow fast machining, dimensional stability, and better surface finish on metal parts. We inserts also have low-temperature resistance, good thermal and electrical conductivity, and many other excellent properties. We is the name you can trust for world-class carbide inserts.

We cutting tool inserts comes also with other designs, sizes, and grades. Aside from that, we also offer carbide inserts, cutting inserts, cermet inserts, tungsten carbide inserts, machining inserts, and lathe inserts. There are thousands of types of cutting tools and smart cutting solution.