Understanding Laser Cutting Machine Prices: Factors, Types, and Tips for Buyers

October 28, 2024

Laser cutting machines have become essential tools across a wide range of industries, including automotive, aerospace, manufacturing, jewelry, and even art. They offer unmatched precision, versatility, and speed, making them the go-to option for many businesses. But with their advanced capabilities comes a substantial price range. Whether you're a small business or a large manufacturing company, understanding the factors that impact laser cutting machine price can help you make a smarter, more cost-effective decision. Here’s a detailed look at what influences the price of a laser cutting machine and how to find the right one for your needs.

1. Types of Laser Cutting Machines and Their Price Range

Laser cutting machines come in various types, each suited for specific applications and materials. Here’s a quick breakdown of the main types and their approximate price ranges:

1.1 CO₂ Laser Cutting Machines

CO₂ lasers are versatile, suitable for cutting and engraving non-metallic materials like wood, acrylic, and glass, as well as some metals with specific configurations. They are commonly used in signage, interior decor, and craft industries.

- Price Range: $3,000 - $20,000 (for smaller models) to $100,000+ for industrial-grade machines.

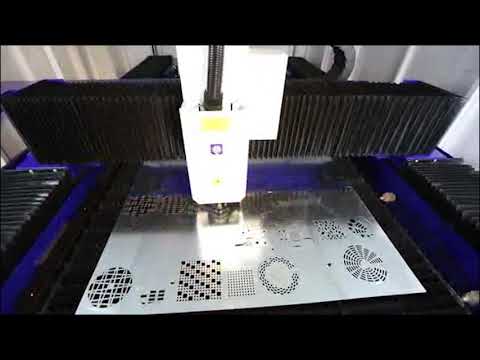

1.2 Fiber Laser Cutting Machines

Fiber lasers are ideal for cutting metals like stainless steel, aluminum, and copper. Their efficiency and speed make them popular in heavy-duty industries like automotive and aerospace.

- Price Range: $20,000 - $200,000+ depending on power and capabilities. Industrial fiber lasers with high power (e.g., 10 kW+) are at the higher end.

1.3 Diode and Crystal (Nd

) Lasers

These lasers are specialized for applications like marking, welding, and cutting thin metals. However, they are less common for extensive cutting operations than fiber or CO₂ lasers.

- Price Range: $10,000 - $50,000+ depending on the application and power.

2. Key Factors Affecting Laser Cutting Machine Prices

2.1 Power of the Laser

The power of a laser is one of the biggest factors that impact price. Higher power levels enable cutting through thicker materials at faster speeds. For instance:

- Low-Power Machines (up to 500 W): Ideal for thinner materials, engraving, and precision work.

- Medium Power (1,000 - 3,000 W): Suitable for thicker metal sheets and more versatile applications.

- High Power (4,000+ W): These are the most expensive and are primarily used in heavy-duty industries for high-speed, deep cuts.

2.2 Machine Size and Bed Dimensions

Laser cutting machines are available in various sizes, from desktop models to large industrial machines with bed sizes that can accommodate massive sheets of metal. The larger the cutting area, the higher the price, as bigger machines need stronger frames and more robust components.

- Small Desktop Models: Suitable for hobbyists or small-scale projects. Typically, these start at $3,000.

- Large Industrial Models: Designed for large sheets or multiple pieces simultaneously, starting around $50,000+.

2.3 Automation Features

Automation can drastically improve efficiency in production lines, though it does add to the initial cost. Features such as automated loading/unloading, material feeders, and IoT integration for real-time monitoring allow for reduced labor costs and minimal human intervention. Automated systems are common in high-demand industries, like automotive manufacturing, where productivity is essential.

- Basic Models: Manual loading/unloading.

- Fully Automated Models: Higher initial cost but lead to long-term savings and can start around $100,000+.

2.4 Brand and Manufacturer

Well-known brands often command higher prices due to their reputation, quality, and after-sales support. Trusted manufacturers often offer better warranties, customer support, and more reliable parts and servicing. Brands that have been in the industry for years tend to invest more in research and development, resulting in machines with the latest technology and more durable components.

2.5 Additional Features

Laser cutters come with a variety of features that can affect their price:

- Cooling Systems: Higher-powered machines require more advanced cooling systems, which add to the cost.

- Software Integration: Some laser machines come with custom software, enabling design imports, cut pattern optimization, and IoT connectivity.

- Safety Features: Enclosures, ventilation, and fume extraction systems, especially important for high-power lasers, may add to the price.

3. Price Breakdown for Different Applications

Laser cutting machines can be categorized by application, which often determines the kind of machine you need and the price:

- Signage and Crafting: These applications often use CO₂ lasers with moderate power, costing between $3,000 and $20,000 for most needs.

- Metal Fabrication and Manufacturing: Fiber lasers are popular here due to their ability to cut metals with precision. Machines in this category range from $20,000 for basic models to $200,000+ for high-power industrial versions.

- Jewelry and Electronics: Nd

- and fiber lasers are used in these industries for their precision in cutting small, intricate pieces. Expect prices between $10,000 and $50,000 depending on power and additional features.

4. Maintenance and Operating Costs

In addition to the initial purchase price, laser cutting machines incur maintenance and operational costs. Regular maintenance includes cleaning lenses, replacing nozzles, and recalibrating the machine. Operating costs include electricity, gas (for certain lasers), and cooling requirements.

- Maintenance Contracts: Many manufacturers offer maintenance contracts, which range from $1,000 - $5,000 annually depending on the machine.

- Operating Costs: Electricity costs vary by power and usage but can be significant for high-powered industrial machines.

5. Choosing the Right Machine for Your Budget

To make a wise investment, consider your specific business needs, volume, and budget:

Identify Core Requirements: Consider material types, thicknesses, and production volume. This will help you decide if you need a CO₂, fiber, or diode laser, and what power level is appropriate.

Assess Future Needs: If you anticipate growth, consider a machine that can accommodate future demands, such as automation features or a larger cutting bed.

Seek Demos and Quotes: Visit trade shows or manufacturer showrooms, and request live demos if possible. Comparing quotes from multiple vendors can give you a clearer picture of what's available within your budget.

Check Warranty and Support: Machines with a longer warranty and accessible customer support may come with a higher price tag, but they often offer better value through long-term reliability.

Consider Financing Options: Many manufacturers and third-party lenders offer financing or leasing options, which can make it easier to acquire a high-quality machine without a large upfront cost.

6. Final Thoughts: Investing in a Laser Cutting Machine

Investing in a laser cutting machine can significantly boost productivity, improve precision, and reduce waste for many businesses. However, with prices ranging from a few thousand to hundreds of thousands of dollars, it’s essential to thoroughly research and understand the factors affecting these prices. By considering your needs, application types, and future expansion plans, you can select a machine that offers the best value for your investment.

Laser cutting machines continue to evolve with advancements in automation and IoT, paving the way for smarter, faster, and more reliable operations. When chosen thoughtfully, a laser cutting machine can become a powerful asset for your business, improving not only your productivity but also your bottom line in the long run.

Leave a Reply

Related Products

You Might Like Also

What is a Fiber Laser Cutting Machine Price in India?

Laser cutting machines can provide businesses with fast and efficient ways of cutting and engraving metal. Metal cutting using fiber lasers is not just more efficient than other methods but also requires less deburring and finishing after cutting is completed. Read More

CO2 vs. Fiber Laser Machine: Which One Is Better?

The wavelength is the key distinction that defines the types of materials that each laser can treat. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have a lower range than CO2 lasers in general. Read More