Machine safety fencing, also known as machine guarding or perimeter guarding, refers to physical barriers or enclosures installed around machinery or equipment to protect workers from hazardous areas and prevent unauthorized access. The primary purpose of machine safety fencing is to minimize the risk of accidents and injuries in industrial settings where heavy machinery and equipment are operated.

Here are some key points about machine safety fencing:

Safety Compliance: Occupational health and safety regulations often mandate machine safety fencing to ensure compliance with safety standards. These regulations may vary depending on the industry and location.

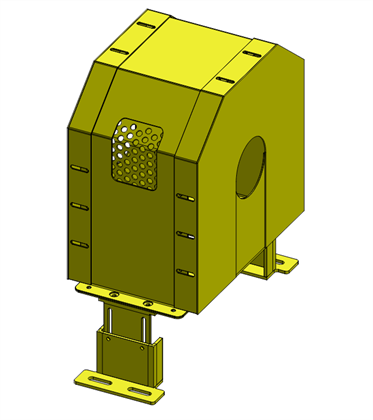

Types of Fencing: Machine safety fencing can come in various forms, including wire mesh panels, polycarbonate sheets, steel bars, or a combination of these materials. The choice of fencing depends on factors such as the level of protection required, the type of machinery being guarded, and environmental conditions.

Access Points: While machine safety fencing is designed to restrict access to hazardous areas, it should also incorporate access points such as doors or gates for authorized personnel to enter when necessary. These access points are often equipped with interlocking mechanisms or safety switches to ensure that the machinery stops operating when the gate is opened.

Visibility and Communication: Clear visibility of machinery and warning signs on the fencing are crucial for communicating potential hazards to workers. Visibility can be achieved through transparent panels or strategically placed warning labels and signage.

Customization: Machine safety fencing solutions can be customized to fit the specific requirements of different industrial environments. This may include considerations such as the layout of the machinery, workflow patterns, and the need for temporary access during maintenance or servicing.

Maintenance and Inspection: Regular maintenance and inspection of machine safety fencing are essential to ensure its effectiveness over time. This includes checking for any damage or wear and tear, repairing or replacing components as needed, and verifying that safety features such as interlocks are functioning correctly.

Integration with Safety Systems: Machine safety fencing is often integrated with other safety systems such as emergency stop buttons, light curtains, and safety sensors to provide comprehensive protection against accidents and ensure swift response in case of emergencies.

Leave a Reply

Related Products

You Might Like Also

chain belt drive guard

V Belt/Chain Drive guards fully enclosed V-Belt Safety Guards, gear drive, and belt drive power transmission system to prevent access to the pinch points around the conveyor belts, fan drives, blower drives, compressor, grinder, and crusher equipment. It helps to keep safe worker/operators around the drive from entanglements Read More

pump coupling safety guard

The pump coupling Guard prevents access to exposed pinch-points around couplings and rotating shaft applications. This guard is designed for the 360 degrees guarding concept. These guards are ANSI/OSHA compliant. Read More

bench grinder machine safety guard

bench grinder machines are critical to protect operators from potential hazards such as flying debris, sparks, and accidental contact with the grinding wheel. Read More

Lathe machine safety guard

r lathe machines are essential to protect operators from potential hazards such as flying debris, rotating parts, and accidental contact with moving components. Read More

safety guards

Increase operator safety by machine perimeter guarding with the highest quality and visual appalling safety fence Read More

drilling machine safety guard

Drilling machine safety guards are crucial for protecting operators from potential hazards when using a drilling machine. These guards help prevent accidents and injuries that can occur due to contact with rotating drill bits, flying debris, or other moving parts of the machine. Read More

Comments

Industrial times need to be equipped with such safety equipment. Appreciate your introduction here.

Build Now GG offers unlimited ammo and realistic ballistics. Master your weapons and dominate!